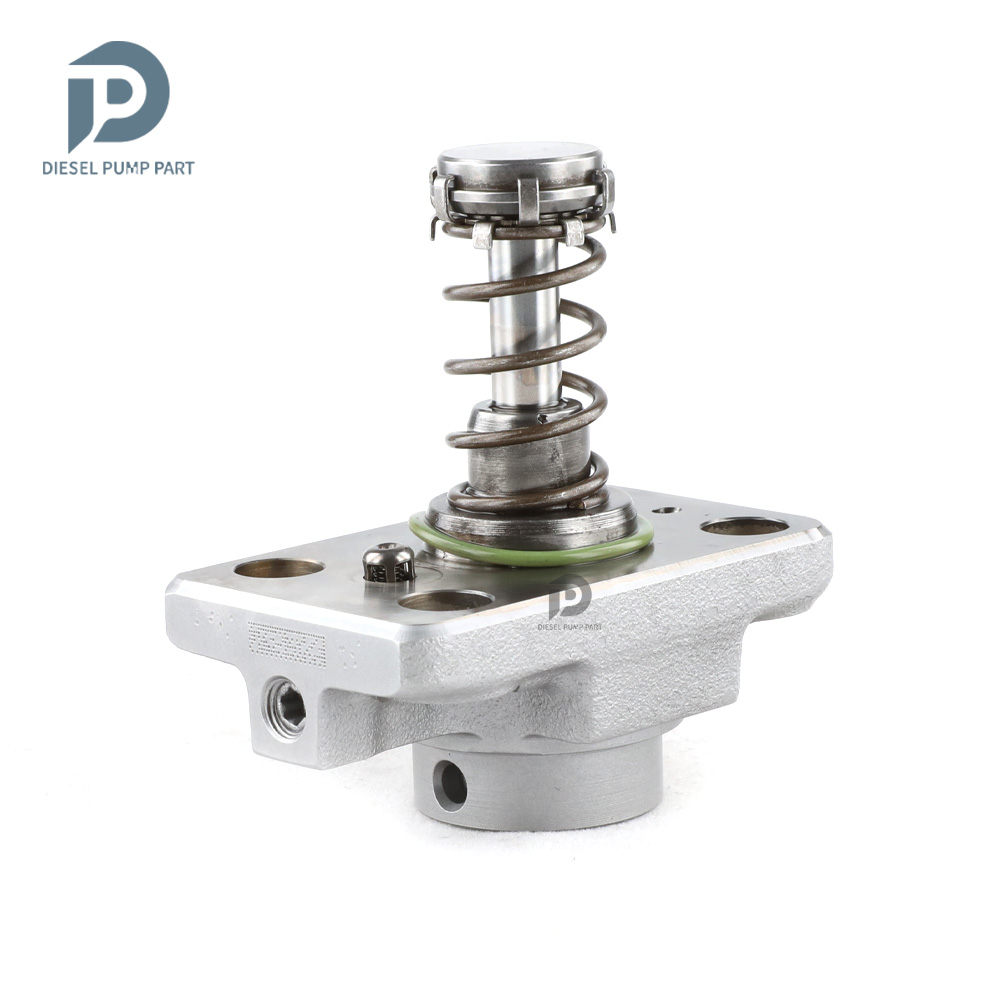

1. F00F0P1006 Diesel Pump Plunger Part Number Location

|

No. |

Name |

|

A |

Nameplate, logo, part number |

2. F00F0P1006 Diesel Pump Plunger Installation Precautions

(1) The replacement of the diesel pump plunger must strictly follow the electrical system, the approved pressure of the low-pressure fuel intake system, the approved pressure of the high-pressure fuel circuit system, and fuel system replacement consumables requirements (including the low-pressure fuel circuit system filter and the high-pressure fuel circuit) specified in the vehicle engine maintenance manual.

(2) Replacement of wearing parts of the fuel system, cleaning requirements for the connection between the fuel system and the diesel pump plunger, the fitting clearance of the diesel pump plunger connection, the installation angle and tightening torque of the diesel pump plunger, the fitting clearance of the intake system, and the fitting clearance of the exhaust system to ensure the service life of the engine and the normal operation of the diesel pump plunger.

(3) When installing the diesel pump plunger on the engine, it is necessary to clean the engine block, cylinder head and other parts connected to the diesel pump plunger, and ensure that there is no dust, carbon deposits, water, rust spots, etc.

(4) When installing the diesel pump plunger on the engine, please carefully check the components related to the installation of the diesel pump plunger, such as the diesel pump plunger pressure plate, screw, diesel pump plunger rod and other accessories are not deformed, and install it in strict accordance with the operation steps of the engine maintenance manual.

(5) It is forbidden to operate the bare diesel pump plunger for a long time in an environment with serious dust pollution and corrosion to iron products.

(6) It is forbidden to operate the bare diesel pump plunger for a long time in a strong magnetic field environment.

3. F00F0P1006 Diesel Pump Plunger Causes of Being Damaged

- Didn’t operate properly according to engine maintenance manual during disassembly or installation, resulting in damage to the diesel pump plunger.

- The fuel oil used for the vehicle does not meet the standard cause damage to the diesel pump plunger, such as: the water content in the fuel oil exceeds the standard, iron powder, aluminum powder, sulfide impurities exceed the standard, etc.

- The engine is not regularly maintained according to the engine maintenance manual (please refer to the vehicle maintenance manual for the maintenance mileage). For example, failure to replace the lubricating oil of the engine system for a long time will cause abnormal wear of the engine, excessive exhaust gas volume or a large amount of carbon deposits inside the engine. The filter is not replaced during maintenance or the replaced filter cannot reach the original filter standard. all above reasons can cause damage to the diesel pump plunger.

- The abrasion of the diesel pump plunger produces iron powder and aluminum powder enter the diesel pump plunger and cause damage to the diesel pump plunger.

- The deformation and abrasion of fuel tank result in iron powder or aluminum powder entering the diesel pump plunger and causing damage to the diesel pump plunger.

- The diesel pump plunger is damaged due to replacement or adjustment of the relevant parts of the diesel pump plunger. For example, the valve clearance does not meet the standard after the engine is repaired, the replacement or modification of the wiring harness connected to the diesel pump plunger fails to meet the original standard.

- The engine is overheated and overloaded for a long-time working result in damage to the diesel pump plunger.

- The diesel pump plunger will be damaged naturally at the end of its working life.

- The diesel pump plunger is magnetized (diesel pump plunger parts’ magnetic exceeded) causing the diesel pump plunger to not work properly.

- Before replacing the diesel pump plunger, please check the engine parts carefully according to the engine maintenance manual to avoid the diesel pump plunger being damaged again after replacement.

4. F00F0P1006 Diesel Pump Plunger Storage Standard

- Choose a Suitable Storage Place

The warehouse and cargo yard where the diesel pump plunger is stored should be kept clean and dry, and away from the factory buildings that generate harmful gases and dust; do not mix with acids, alkali, salt, and other substances; the storage place should have a good drainage system; the cargo yard should be flattened with gravel or furnace ash etc. to enhance the water permeability of the surface layer to keep the reservoir area dry.

- Strict Requirements of Warehousing

Strict inspections should be carried out when the diesel pump plungers are put into storage, the surface cleaning work should be done well to remove water traces, oil stains, ashes, and other dirt, remove the rust and do anti-rust treatment in time. Packaged diesel pump plungers must be protected from damage.

- Keep The Warehouse Dry And Preventing Moisture

The relative humidity is usually below 70% for the diesel pump plungers placed in the room, and the corrosion of the diesel pump plungers is significantly reduced.

Pump plungers must be stored in the warehouse, and they are forbidden to store in the same warehouse with commodities with high water content.

- Stack Properly

After the diesel pump plunger is exposed to rain, the corrosion rate will increase significantly. The purpose of sealing is to isolate the diesel pump plunger from rainwater and humid air, so the warehouse window should be checked in time to avoid rainwater entering the warehouse.

If the diesel pump plunger package is damaged, it should be repaired or replaced; when the package is damp, the packaging material should be dried; if the original anti-corrosion and oil applied at the factory is found to be damaged or dried up, it should be cleaned and re-applied oil in time.

- It is forbidden to leave the diesel pump plunger exposed in the air for a long time.

- It is forbidden to store acids, alkalis, salts, and other substances together with the diesel pump plunger.

- The unpacked diesel pump plunger must be rust-proof during secondary storage.

5. Copyright Statement

The content of “F00F0P1006 Diesel Pump Plunger Encyclopedia” is protected by copyright and is the property of www.dieselpumppart.com. Any commercial use, including copying, distribution, modification, or creation of derivative works, is strictly prohibited without written permission from www.dieselpumppart.com. All image rights are reserved to Shenzhen Shumatt Technology Co., Ltd.

For any inquiries regarding the use of the “F00F0P1006 Diesel Pump Plunger Encyclopedia,” please contact us at hison@shumatt.com.